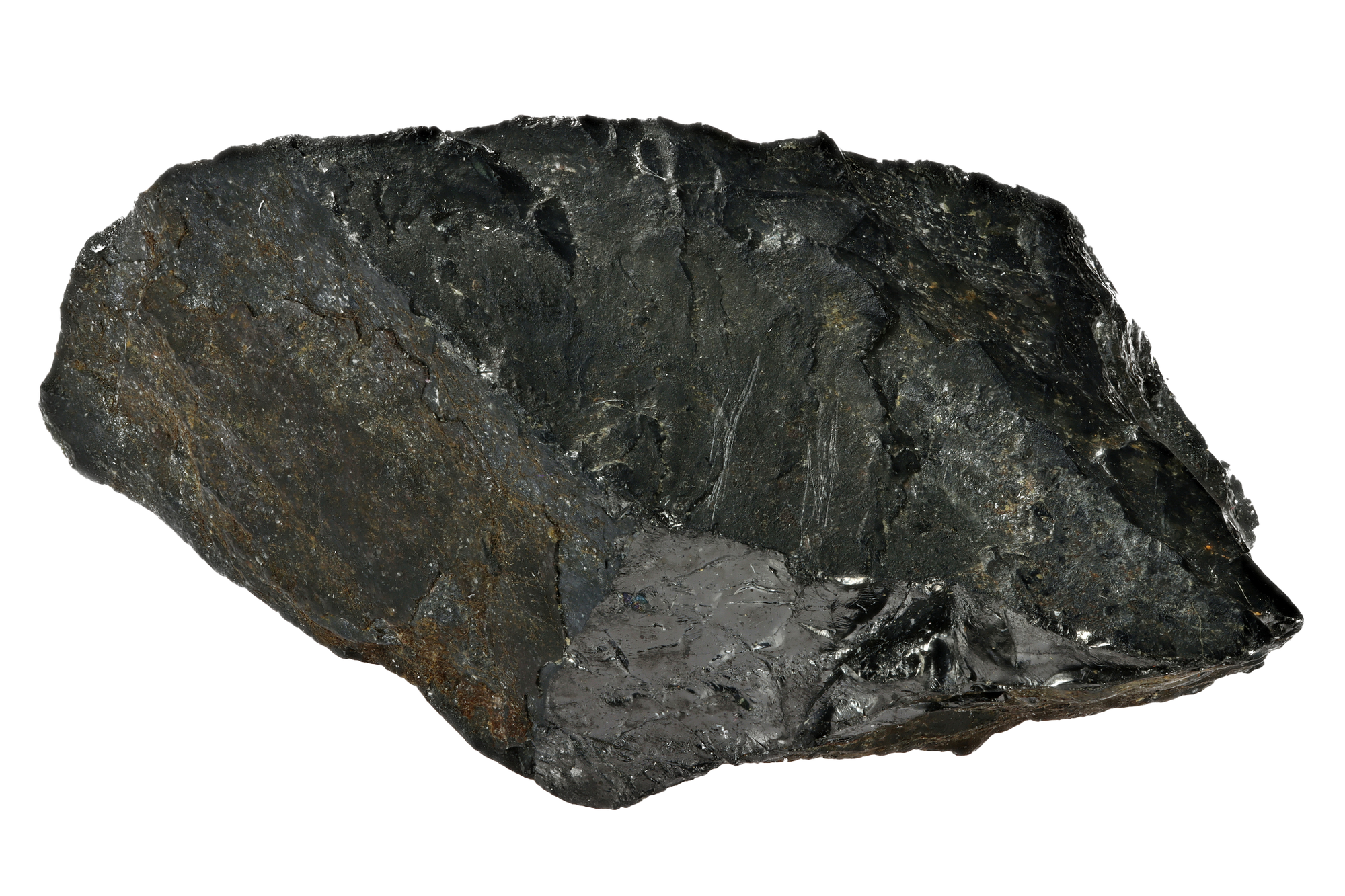

Titanium Scrap Recycling

Quest Alloys excels in identifying, appraising, and recycling all types of titanium and titanium-containing materials, including titanium solids, wire, shavings, and processing remnants.

Quest Alloys excels in identifying, appraising, and recycling all types of titanium and titanium-containing materials, including titanium solids, wire, shavings, and processing remnants.

We are specialists in titanium refining, offering our expertise in inspection, sampling, and verification services to clients globally. Additionally, we manage all logistics related to the import and export of metals and alloys, providing competitive pricing for titanium.

As an ISO 9001 certified processor and supplier, we pride ourselves on fast service, prompt payment and compliancy with all major air and vacuum smelters. Call us and discover how simple tantalum refining can be. We pay for and move your materials from anywhere in the world with superior efficiency to ensure prompt delivery of goods to our global consumers.

Titanium boasts one of the highest strength-to-weight ratios among metals and is distinguished by its remarkable corrosion resistance. A significant portion of the world's titanium is utilized in aerospace engineering for the production of aircraft components such as engine parts, airframes, and landing gear, owing to its ability to withstand extreme temperatures and corrosive environments. Titanium's alloying with other metals enhances its strength and heat resistance, making it indispensable in aerospace designs.

Beyond aerospace, titanium's biocompatibility makes it a preferred material for medical implants, including joint replacements and dental implants, due to its ability to withstand bodily fluids without corroding. In the chemical industry, titanium is used in process equipment to resist corrosion by acidic materials.

The recycling of titanium scrap is vital, recovering valuable material from manufacturing processes and used products. Annually, recycling helps return significant amounts of titanium to the supply chain, helping to stabilize prices despite the metal's relative scarcity and high demand across various industries.