Tantalum capacitors are a type of electrolytic capacitor that utilizes tantalum metal for the anode, known for their high capacitance per volume and excellent stability. These capacitors are widely used in electronic devices due to their ability to store a large amount of charge relative to their size, and their stable performance across a wide range of temperatures and frequencies. They are also valued for their long lifespan and reliability, particularly in demanding applications. These capacitors contain tantalum, a rare and valuable metal, making the recycling of tantalum capacitors a crucial process for companies looking to maximize value from electronic scrap while promoting sustainability.

In addition to their performance benefits, proper identification of tantalum capacitors through their markings is essential for recycling and reuse. Understanding how to correctly identify these components and their polarity ensures accurate recycling and prevents costly mistakes.

This guide explores the process of tantalum capacitor recycling, providing insight into tantalum cap marking, how to identify these capacitors, and the significance of proper handling. By the end, you’ll understand why partnering with a trusted recycler like Quest Metal is vital for selling your tantalum scrap and supporting a circular economy.

Tantalum capacitor recycling involves the extraction and recovery of tantalum from electronic waste (e-waste). The process entails identifying, sorting, and processing electronic components that contain tantalum, particularly tantalum capacitors, to recover the precious metal. Given that tantalum is a rare element, its recycling is an important aspect of resource conservation and cost savings for industries relying on electronic components.

Tantalum capacitors are used in a wide range of industries, including aviation and energy, due to their stability, reliability, and ability to withstand extreme conditions. However, when electronic devices reach the end of their lifecycle, disposing of them carelessly results in valuable tantalum being lost. Recycling allows for the reintroduction of tantalum back into the supply chain, reducing the demand for mining and extraction.

Tantalum capacitor recycling is a process aimed at recovering tantalum and other valuable materials from discarded capacitors, which is crucial due to the scarcity of tantalum and the environmental impact of mining it. The recycling process begins with the collection and sorting of electronic devices containing tantalum capacitors. These capacitors then undergo pyrolysis, a thermal decomposition process that breaks down the epoxy resin encasing the tantalum core. Once this step is complete, the tantalum-rich core is separated from other materials, often using mild acid leaching to remove impurities such as manganese dioxide. The separated tantalum is further purified and recovered, yielding a significant amount of this valuable metal and reducing the need for new mining.

The benefits of tantalum capacitor recycling are significant. Environmentally, it lessens the demand for newly mined tantalum, reducing the ecological damage associated with mining operations. In terms of resource efficiency, recycling helps maintain a stable supply of tantalum, which is critical for the electronics industry. Economically, it offers value by recovering a high-priced metal, making the process financially beneficial.

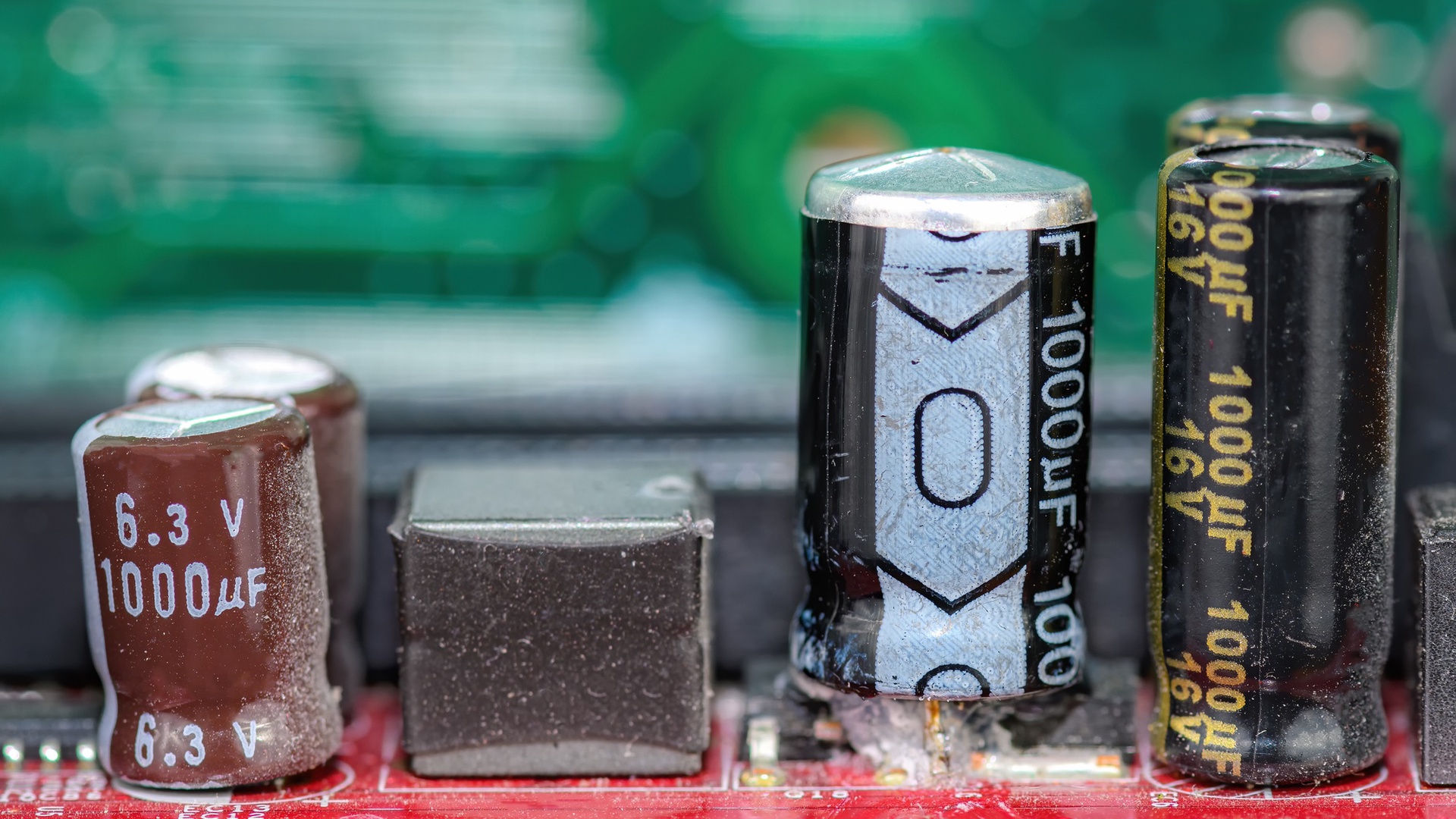

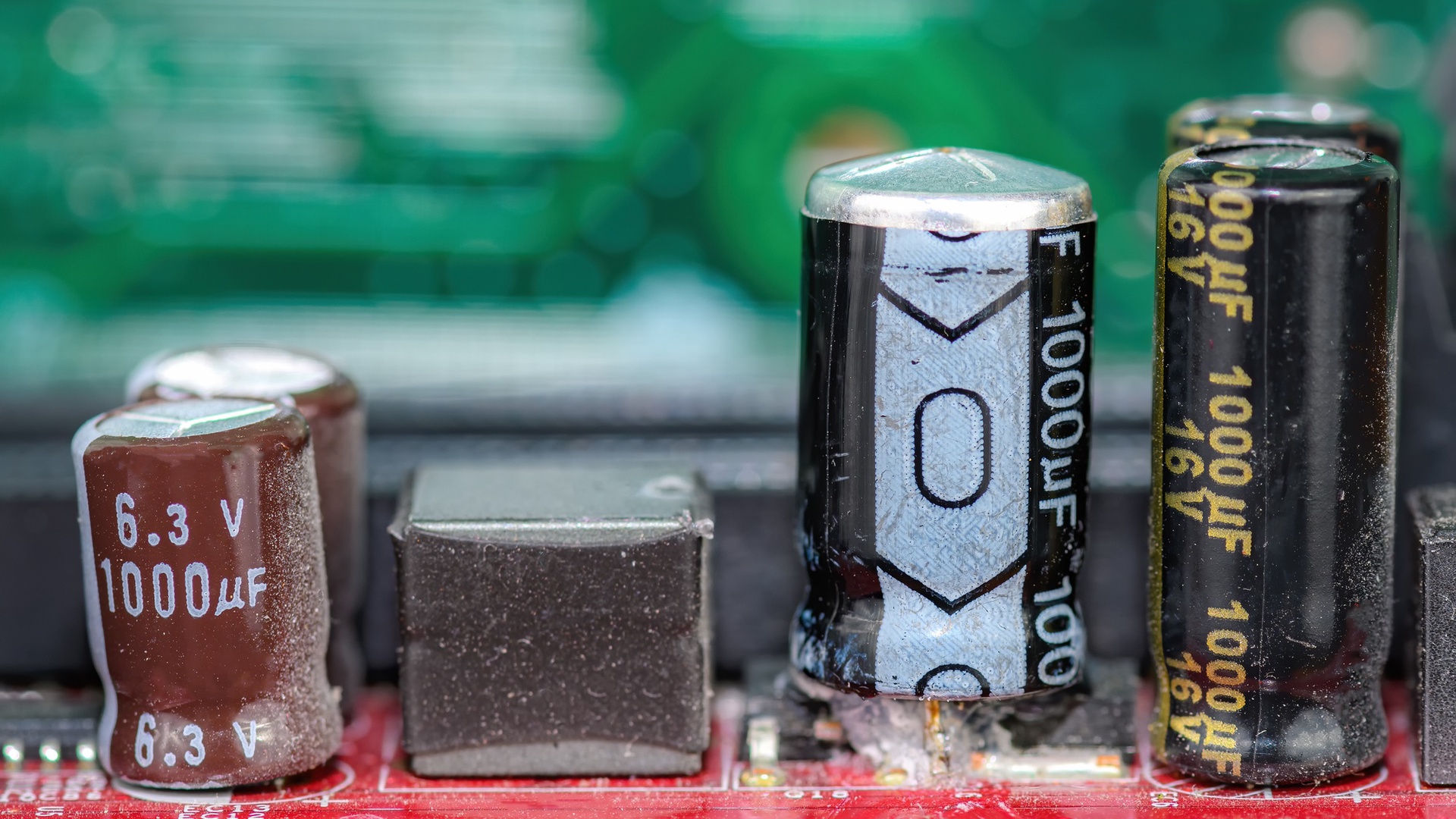

Tantalum cap marking plays a pivotal role in recycling. These markings help identify the capacitor type, voltage rating, polarity, and manufacturer, making it easier for recyclers to determine which capacitors contain tantalum. Without proper identification, it becomes difficult to sort and recycle these components efficiently.

Markings on tantalum capacitors can be found on the body of the capacitor, and they often include numbers or codes representing the capacitance value, voltage rating, and tolerance. These markings also indicate whether a capacitor is of a polymer type, a critical distinction for recyclers. Polymer capacitor markings are different from traditional tantalum capacitors, though both may be valuable in the recycling process.

Proper identification of tantalum capacitors is essential for recycling. Tantalum capacitors can often be recognized by their small size and distinctive markings. The following steps can help in identifying them:

Tantalum capacitors are polarized, which means they must be connected in the correct orientation to function properly. This is crucial not only in electronics design but also in recycling. Incorrect identification of tantalum capacitor polarity can lead to damage or destruction during recycling processes. Polarity markings, typically a "+" sign for the positive terminal, help ensure capacitors are recycled correctly, preserving their value.

Recycling tantalum capacitors presents significant economic and environmental benefits. Tantalum is classified as a conflict mineral, meaning its extraction can have ethical implications related to human rights and environmental degradation. By recycling tantalum, companies can reduce the need for new mining, decrease environmental harm, and support more ethical supply chains.

For businesses in industries such as aviation and energy, recycling tantalum capacitors can help offset costs. Selling recyclable tantalum to trusted buyers like Quest Metal ensures that companies benefit financially while reducing waste. The recycling process recovers tantalum that can be used in the production of new capacitors, creating a sustainable cycle for this valuable material.

Given the complexities involved in identifying and recycling tantalum capacitors, it is critical to work with an experienced recycling partner. Quest Metal specializes in the recycling of tantalum capacitors and other valuable electronic components. We ensure the efficient recovery of tantalum, maximizing the value of your scrap while adhering to environmental standards.

Our expert team understands tantalum cap markings and how to identify and process electronic components containing tantalum. We offer competitive prices for tantalum scrap and provide seamless recycling solutions to companies across the aviation, energy, and defense sectors.

If your company is looking to sell tantalum capacitors or other electronic components for recycling, Quest Metal is your trusted partner. Contact us today to discuss how we can help you recycle your tantalum capacitor scrap and contribute to a more sustainable supply chain. Maximize the value of your e-waste while supporting ethical resource management by partnering with us.