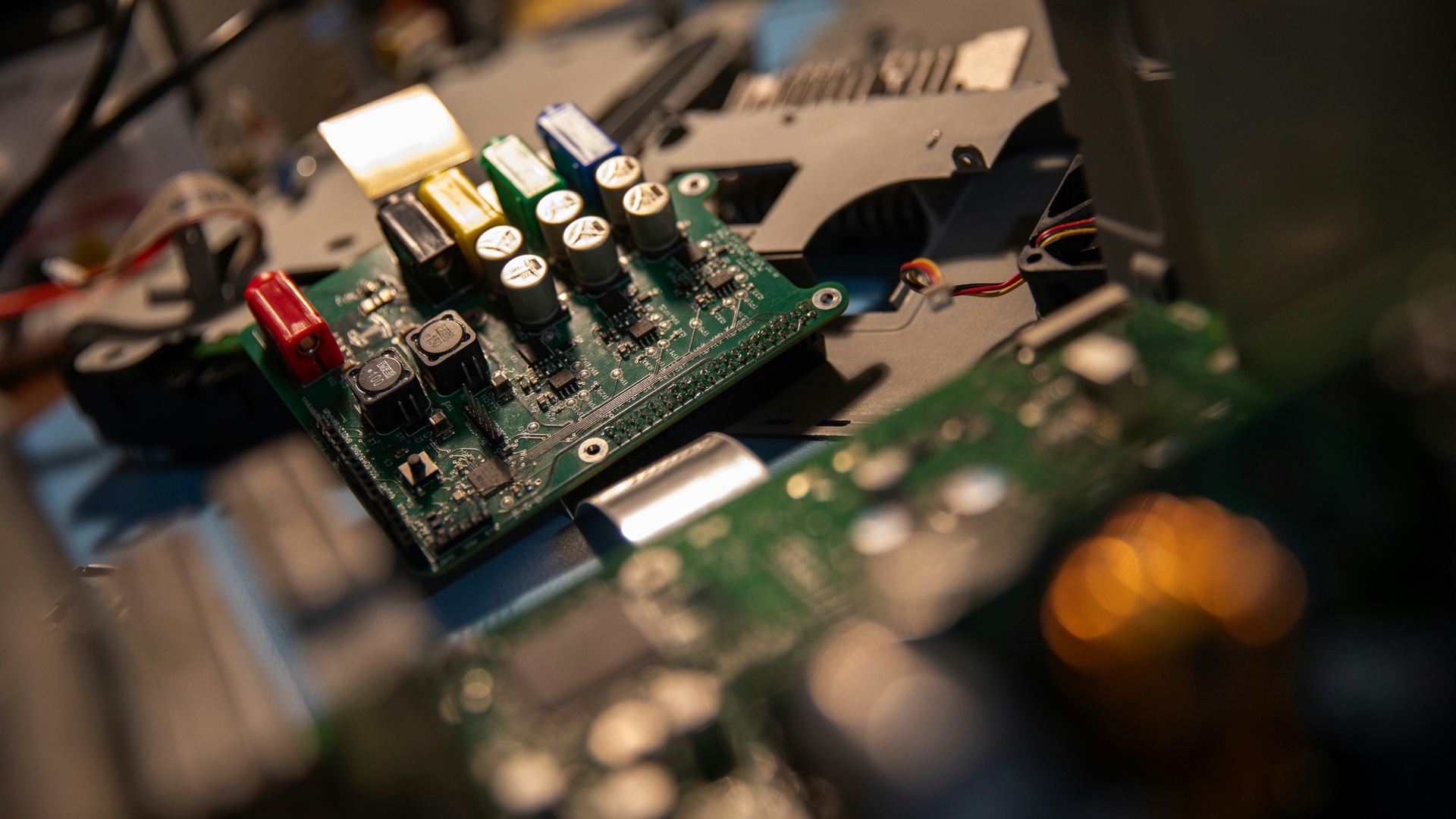

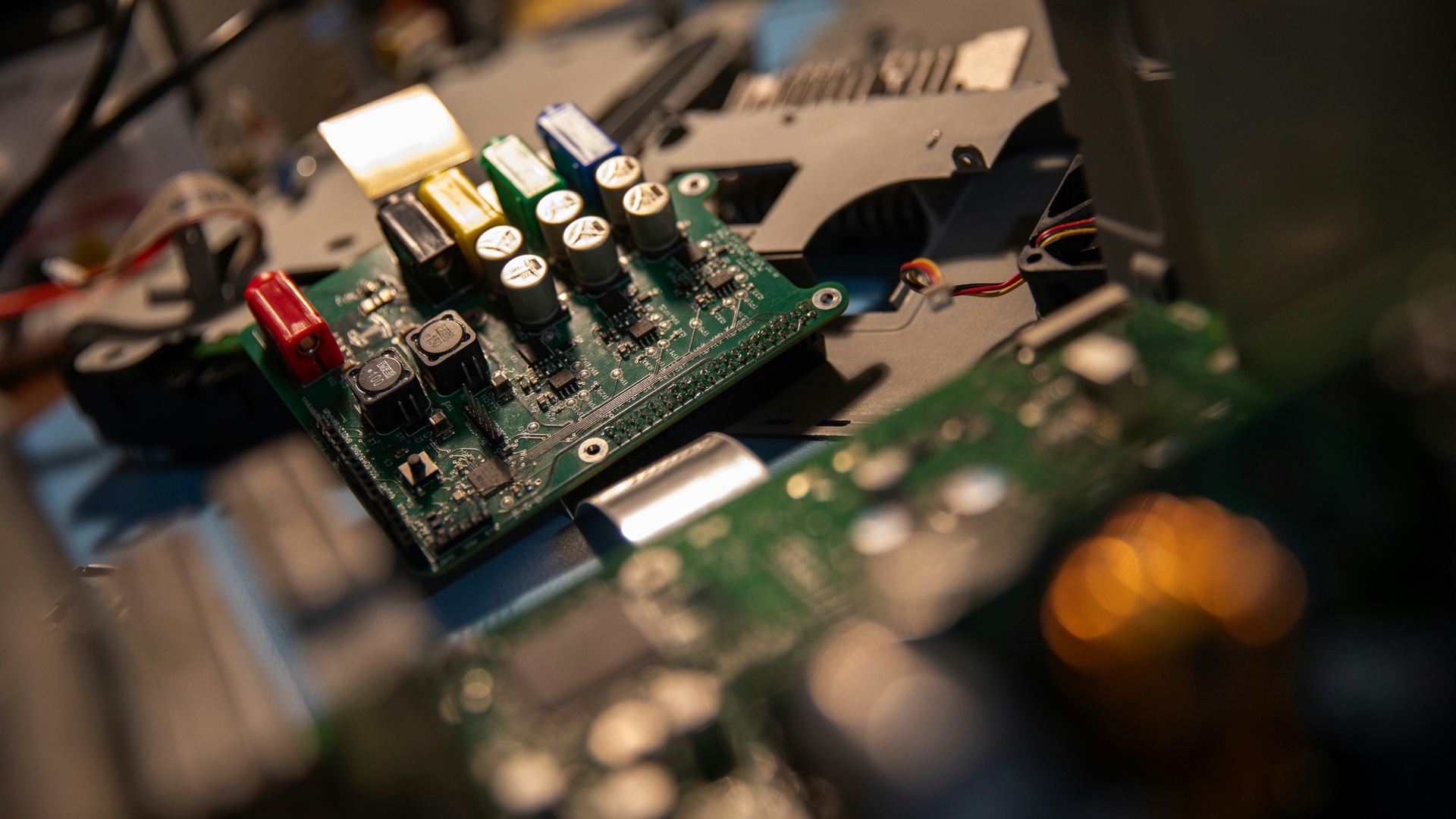

Multilayer Ceramic Capacitors (MLCCs) are ubiquitous, indispensable components in modern electronics. From the smartphones in our pockets and the computers on our desks to critical automotive systems, aerospace equipment, and industrial control units, these tiny, often overlooked devices are essential for circuit stability and signal filtering. Despite their diminutive size, the sheer volume of MLCCs used per device and across global manufacturing makes end-of-life management a significant yet largely untapped opportunity.

Beneath their ceramic exteriors, MLCCs harbor valuable metallic electrodes and termination layers. Historically, older MLCCs (Precious Metal Electrode - PME types) primarily utilized palladium and silver for their conductive layers, making them highly attractive for precious metal recovery. While newer MLCCs (Base Metal Electrode - BME types) have largely transitioned to nickel and, in some cases, copper for cost-effectiveness, they still represent a substantial source of nickel. Furthermore, certain Class 1 MLCCs, particularly NP0/C0G types, can contain rare earth oxides in their dielectric formulations, adding another dimension to their recoverable value.

The economic and environmental case for recycling Multilayer Ceramic Capacitor (MLCC) scrap is undeniable: these ubiquitous, millimeter-scale components—found in counts of hundreds per smartphone, ~1,400 per PC, and up to 5,000 per automobile—concentrate a surprising cache of metals that shifts depending on vintage and voltage rating, with older, precious-metal-electrode (PME) parts harboring palladium-rich Ag-Pd alloys and newer, base-metal-electrode (BME) parts dominated by nickel (plus Cu/Ni-Sn terminations) and rare-earth-doped barium-titanate dielectrics (Dy, Ho, Er, Y, Nd, Sm, etc.). As soaring palladium prices spurred the industry’s migration to cheaper BME designs, legacy high-voltage electronics evolved into especially valuable Pd reservoirs. At the same time, today’s e-waste streams present a parallel opportunity for high-volume nickel and rare-earth recovery. Because roughly one trillion MLCCs roll off assembly lines annually, the aggregated scrap mass—whether culled from post-consumer gadgets or, more efficiently, from homogeneous manufacturing rejects—offers compelling economics: large, non-magnetic ceramic MLCC scrap fetches ≈ US $85 per eight ounces, illustrating how bulk collection flips the negligible value of a single chip into a robust revenue source. Taken together, MLCC recycling not only mitigates resource depletion and landfill burden, but also captures strategic metals critical to battery, catalyst, and magnet supply chains, making tailored recovery processes for both PME- and BME-era capacitors a strategic imperative for a truly circular electronics economy.

Recycling MLCC scrap involves a series of specialized steps that aim to liberate and refine valuable metals efficiently. The process begins with mechanical pre-treatment, where initial steps focus on mechanically separating MLCCs from other circuit board components or mixed e-waste. This is followed by crushing and grinding the materials to reduce the ceramic components to a fine powder, which increases the surface area available for subsequent chemical processing. Screening is then conducted to ensure a uniform particle size.

The next phase of the process employs either thermal treatment or chemical leaching. In some cases, high-temperature thermal treatment, known as pyrometallurgy, is utilized to burn off organic binders and isolate the metal content, thus preparing it for further refining. However, the more common and often preferred method is hydrometallurgical processing. In this approach, the pulverized MLCC material is subjected to acid leaching, using reagents such as nitric acid or aqua regia for precious metals and sulfuric acid for nickel. This step dissolves the target metals into a solution.

Following the leaching phase, the dissolved metals undergo a series of separation and purification techniques. Selective precipitation is achieved by adjusting the pH or adding specific reagents to the solution, enabling the selective precipitation of individual metals, such as palladium, silver, and nickel, as various compounds. Another method at this stage is solvent extraction, which uses organic solvents to extract target metal ions from aqueous solution selectively. Additionally, an electrochemical process known as electrowinning can be used to plate pure metals from solution onto electrodes. The recovered metal compounds are then further refined to achieve high purity, allowing for their reintroduction into the supply chain.

Recycling MLCC scrap offers substantial advantages that significantly contribute to both economic and environmental sustainability. One of the primary benefits is the reduction in reliance on primary mining. By recovering valuable metals such as palladium, silver, nickel, and rare-earth oxides from MLCCs, we can directly reduce demand for virgin materials. This not only conserves limited natural resources but also reduces the environmental impact of mining operations, which often result in habitat destruction and high energy consumption.

Additionally, recycling MLCCs plays a crucial role in lowering the toxicity and volume of electronic waste. By diverting these components from landfills, we effectively reduce the overall amount of e-waste. This effort is vital because it helps prevent the potential leaching of heavy metals into the environment, thereby reducing e-waste toxicity.

Finally, the practice of MLCC recycling embodies the principles of a circular economy. In this system, materials are kept in use for as long as possible, maximizing their value before they are ultimately recovered and regenerated. This approach not only fosters sustainability but also supports the development of a more responsible and sustainable electronics manufacturing industry..

Unlocking the hidden value in MLCC scrap often requires specialized expertise. Companies like us at Quest Metals are at the forefront of high-grade electronics scrap recovery, offering tailored solutions for ceramic capacitor waste and other microelectronic components. They provide comprehensive scrap evaluation, leverage advanced refining technologies to achieve efficient metal extraction, and ensure maximum metal value is returned to their partners. Such specialized partners play a crucial role in transforming what was once waste into valuable secondary raw materials.

For electronics manufacturers, recyclers, and scrap aggregators, the message is clear: the tiny components within your waste streams hold significant untapped value. Segregating MLCC-containing waste and exploring professional recovery solutions is not just an environmentally responsible choice but a financially astute one. By embracing specialized MLCC recycling, we can collectively contribute to a more sustainable future for the electronics industry, turning waste into a resource and unlocking the hidden wealth in every tiny component.

Multilayer Ceramic Capacitors (MLCCs), though often overlooked due to their diminutive size, are indispensable components in the vast landscape of modern electronics. Their widespread integration, from consumer gadgets to advanced automotive and aerospace systems, leads to an immense accumulation of MLCC scrap within the global e-waste stream. This article has illuminated the substantial hidden value in these tiny components, particularly their rich content of precious metals like palladium and silver (especially in older models), as well as valuable base metals such as nickel and rare-earth elements.

The strategic recycling of MLCC scrap presents a compelling dual advantage. Economically, it offers a lucrative avenue for resource recovery, transforming what was once waste into a profitable asset. This is achieved through the high aggregated metal value of MLCCs when collected in bulk, the cost-effectiveness of recycling compared to primary mining, and the opportunities for revenue generation and job creation within the specialized recycling industry. Environmentally, MLCC recycling delivers profound benefits by significantly reducing reliance on primary mining, which is a resource-intensive and environmentally damaging activity. It also plays a crucial role in lowering the overall toxicity and volume of e-waste, preventing hazardous materials from contaminating ecosystems. Fundamentally, MLCC recycling is a tangible and high-impact example of circular economy principles in action, ensuring that valuable materials are kept in circulation and continuously reused in new electronic components.

The evolution of MLCC metallurgy, from palladium-silver-rich PME systems to nickel-dominant BME systems, underscores the need for sophisticated and adaptable recycling processes. Mechanical pre-treatment, followed by advanced thermal or hydrometallurgical isolation and precise refining steps, is essential to maximize the recovery and purity of these valuable metals. The technical feasibility and high recovery rates demonstrated by these processes highlight the immense potential for unlocking this hidden value.