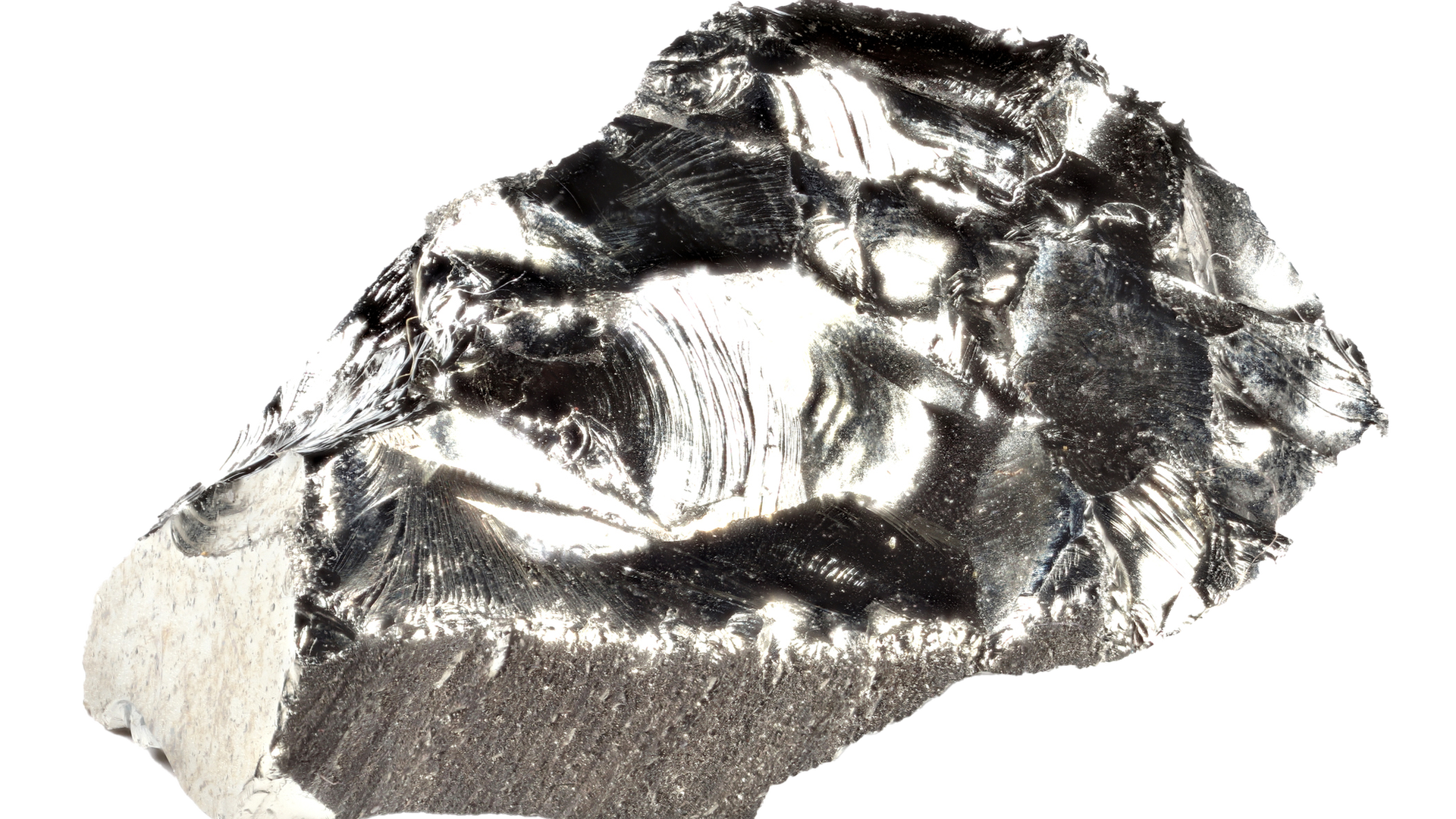

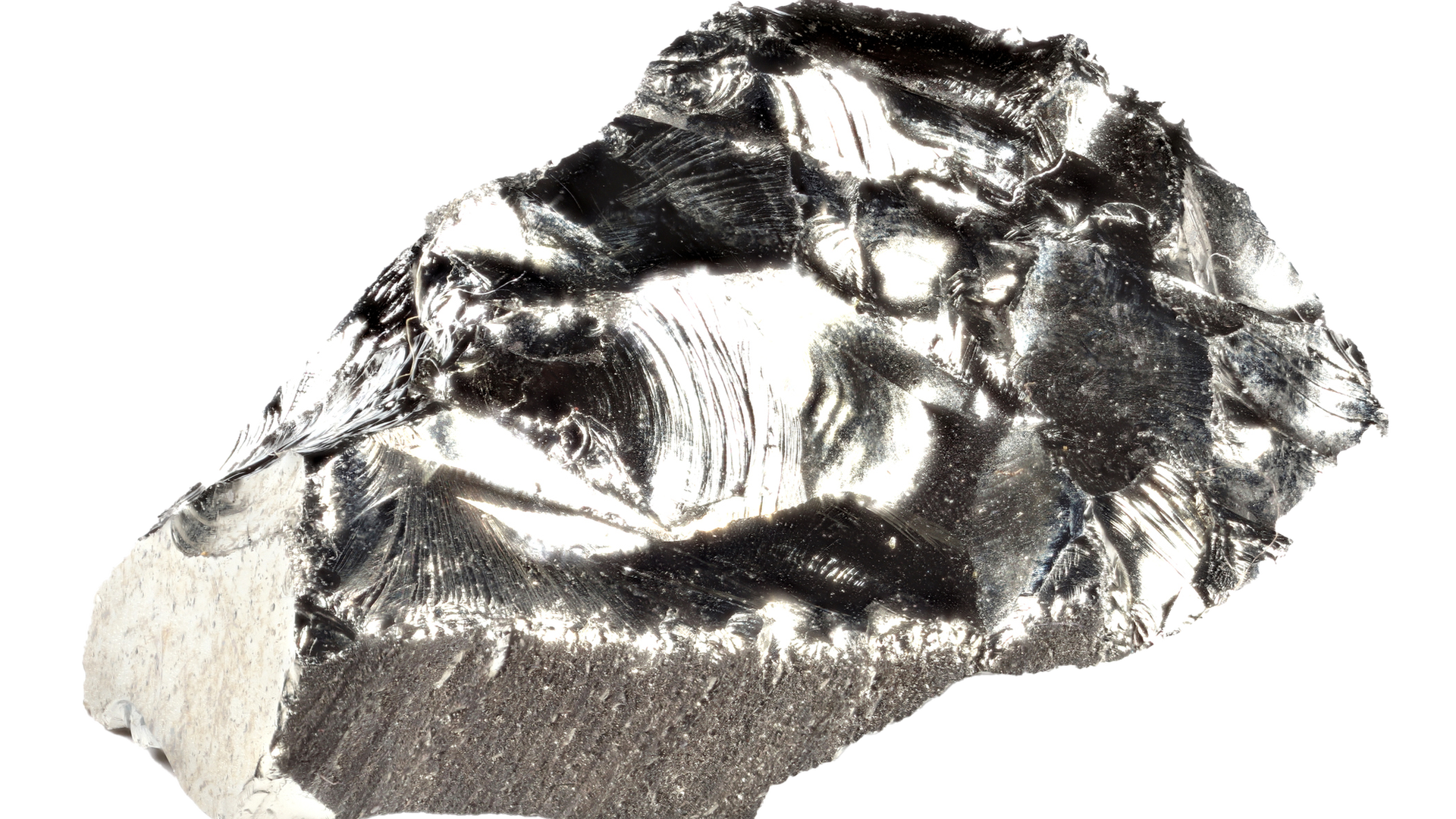

Osmium holds the distinction of being the rarest precious metal and, indeed, the rarest stable element found in the Earth’s crust. It naturally occurs as a trace element, primarily in platinum ores and the mineral osmiridium (an alloy with iridium). Its extraction is complex and typically occurs as a byproduct of refining other metals, such as platinum, gold, and nickel. This inherent rarity and the intricate production process underscore the increasing significance of recycling osmium.

The global osmium recycling market is experiencing significant growth, driven by several key factors. One of the primary motivators is the heightened focus on sustainability and environmental concerns. As the world increasingly prioritizes sustainable practices and aims to reduce the environmental impact associated with mining, recycling has emerged as a crucial alternative for sourcing this rare metal.

In addition to sustainability, effective resource management plays a vital role in the growth of the recycling market. By recycling osmium, we conserve a scarce resource and ensure a more consistent supply chain, thereby reducing dependency on primary mining operations. This aspect becomes even more urgent in light of increasing global regulatory pressure, which mandates waste reduction and promotes recycling initiatives.

Another factor contributing to this expansion is the growing industrial demand for osmium’s unique properties. Industries such as automotive, electronics, and chemicals rely heavily on osmium and its applications, including catalysts, durable electrical contacts, and high-performance alloys. This rising demand fuels the need for recycled osmium to meet various industrial requirements.

Moreover, recycling offers economic incentives, with potential cost savings relative to primary extraction and processing methods. Advances in recycling technologies, particularly pyrometallurgical and hydrometallurgical techniques, have also played a significant role. These innovations improve efficiency, recovery rates, and the purity of recycled osmium, thereby increasing its viability for high-tech applications. As a result, the osmium recycling market is poised for continued growth in the coming years.

Osmium for recycling is primarily recovered from several key sources. One of the main contributors is industrial waste arising from manufacturing processes that use osmium, such as catalyst production and alloy manufacturing. Additionally, with the rapid increase in electronic device consumption, electronic waste (e-waste) has become a significant source of osmium. Discarded electronics often contain small amounts of osmium in components such as electrical contacts, making them a growing source for recovery.

Another source, although somewhat niche, is jewelry scrap. High-end jewelry containing osmium can yield valuable material for recycling. Furthermore, end-of-life medical devices, scientific instruments, and spent catalysts contribute to the pool of recyclable osmium, thereby increasing the diversity of sources from which it can be recovered.

Several methods are employed to recover osmium, each suited to different materials and conditions. One of the most established approaches is pyrometallurgical processing, which involves high-temperature methods such as smelting. These techniques are particularly effective for processing large volumes of waste, especially industrial scrap.

Another significant method is hydrometallurgical processes. These techniques leverage aqueous chemistry, such as leaching and solvent extraction, making them particularly well-suited for more complex materials, such as e-waste, where osmium concentrations may be low. Hydrometallurgy is often regarded as more environmentally friendly because it typically involves lower energy consumption and lower emissions than pyrometallurgical methods.

In addition to these established techniques, research is continually advancing alternative methods. Emerging processes such as bioleaching, which employs microorganisms, and electrochemical techniques are being explored for their potential to enhance efficiency and provide additional environmental benefits in osmium recovery.

Ultimately, the selection of a recovery method depends on various factors, including the source material, the desired purity of the osmium, the volume of material to be processed, and the associated economic considerations. In many cases, a combination of these methods is employed to achieve optimal recovery results. To ensure that the recycled osmium meets the rigorous standards required for demanding applications, analytical techniques such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS) play a crucial role in verifying the purity of the final product.

Thanks to its exceptional properties, recycled osmium finds a variety of applications that mirror those of primary osmium. One of its key applications is as a catalyst, where it plays an essential role in chemical synthesis and in automotive catalytic converters. Additionally, recycled osmium is highly valued in the production of electrical contacts, prized for its durability and conductivity, making it a staple in high-reliability electronics.

In alloy production, recycled osmium is used alongside platinum-group metals to create materials that are both extremely hard and durable, suitable for high-stress applications such as aerospace components and, historically, for pen tips. Beyond these applications, it is also used in scientific instruments and medical devices and is increasingly popular in high-end jewelry.

The primary consumers of recycled osmium span several industries, including the automotive, electronics, chemical, medical, and scientific sectors, as well as the jewelry market. Geographically, the Asia-Pacific region is poised to lead market growth, with a projected compound annual growth rate (CAGR) of 7.5%, driven by rapid industrialization and substantial e-waste generation. Meanwhile, North America and Europe are also key markets, with projected CAGRs of 6.2% and 6.0%, respectively, attributed to their established recycling infrastructures and strong regulatory frameworks. In contrast, while Latin America and the Middle East & Africa represent smaller markets, they are still on an upward trajectory, with projected CAGRs of 5.8% and 5.5%.

The market benefits from regulatory tailwinds and growing demand from emerging technologies. However, challenges remain, including the high cost and technical complexity of recycling processes and the variability in the supply and quality of waste feedstocks. Continued innovation in recycling technology and efficient collection infrastructure is key to overcoming these hurdles and fully realizing the potential of osmium recycling. Given the toxicity of certain osmium compounds, such as osmium tetroxide (OsO4), safe handling protocols throughout the collection and recycling processes are paramount.