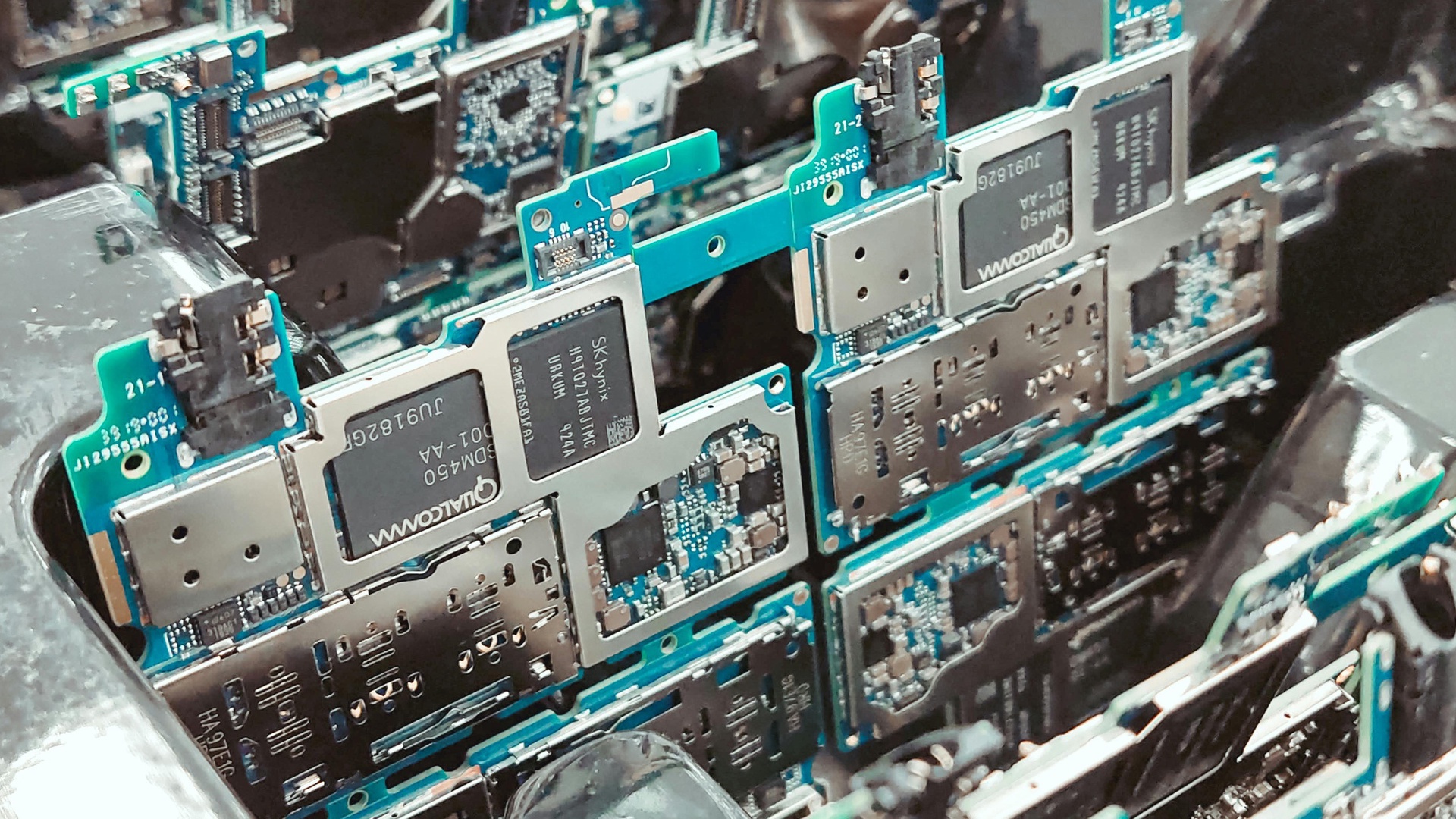

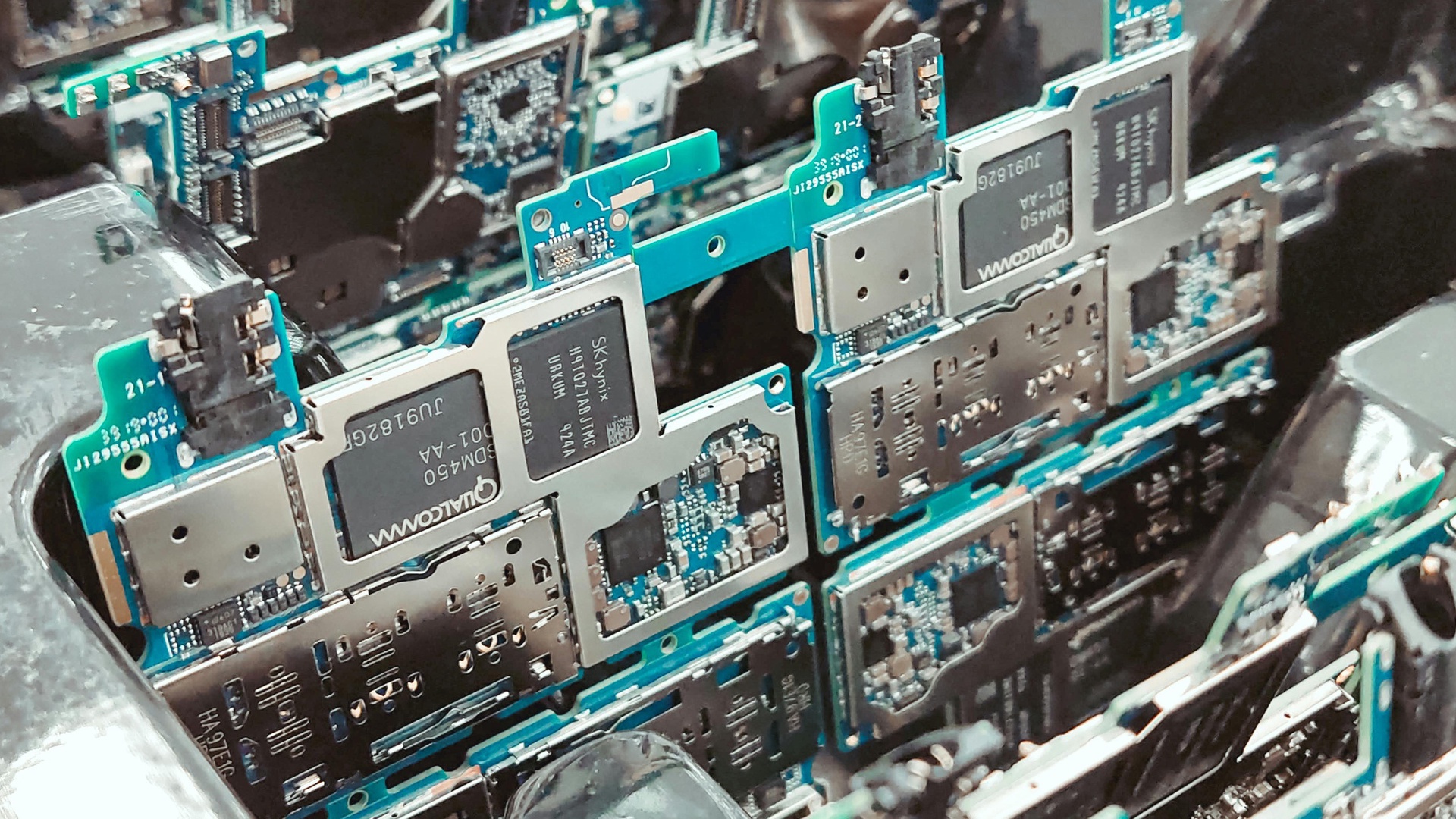

Every time you discard a broken smartphone, outdated laptop, or used-up LED, there's more at stake than just desk clutter. Tucked inside these everyday electronics are rare and valuable elements, so-called critical materials like gallium, indium, and tantalum that might be gone forever once they hit the landfill.

These materials power everything from touchscreens and LEDs to medical devices and military technologies. Yet, despite their essential role and high market value, they’re rarely recycled. That’s not due to lack of importance; it’s because traditional recovery methods are expensive, inefficient, and often hazardous.

But a recent innovation out of West Virginia University’s Department of Mechanical, Materials, and Aerospace Engineering is changing the outlook for critical materials recovery. Our team has developed a groundbreaking microwave-based recycling technology that offers a scalable, cleaner, and more cost-effective way to reclaim these indispensable resources from the growing mountain of e-waste.

Globally, electronic waste (e-waste) is the fastest-growing waste stream, with a staggering 65 million tons generated worldwide in 2024. In the U.S. alone, people discarded about 2.7 million tons in 2018, and likely much more in recent years. Yet, only about 15-17% of this e-waste gets formally documented and processed for recycling. Even worse, roughly half of the electronics that make it to American recycling centers are exported to facilities overseas, where improper and unsafe methods like open-air burning or acid leaching pose serious environmental and health hazards.

In this chaotic processing pipeline, the small but critical elements embedded deep within electronic components, such as tantalum from capacitors or gallium from LEDs, are often ignored or irretrievably lost. Once dumped in landfills or processed into low-grade byproducts like cement, the chance of recovering them vanishes.

Critical materials are special because they’re not just rare, they’re essential. Tantalum, for instance, is a heat-resistant metal used in capacitors found in nearly every smartphone, tablet, laptop, and medical implant. Similarly, indium is crucial for touchscreens, and gallium powers the light in LEDs. These elements are listed on the U.S. Department of Energy’s high-risk critical materials list, meaning their supply is constrained, and disruptions such as trade conflicts or export bans can have national or even global implications.

They’re not cheap either. In 2024, tantalum and gallium were priced at US$170 and up to US$500 per kilogram, respectively, dozens of times more than common metals like copper. Despite their economic value, their microscopic presence and challenging chemistry have long rendered them unfeasible for recovery at recycling plants.

Seeing the enormous gap between potential and practice, our research team asked a simple but profound question: What if we could surgically target and extract these high-value materials from e-waste using a cleaner and more precise method?

Enter microwaves.

Yes, the same fundamental technology behind your kitchen appliance, but on a larger, industrial scale and finely tuned for material science. Microwaves generate electromagnetic waves that cause certain materials, especially those with dipole characteristics such as carbon or water, to oscillate, generating heat internally rather than from an external source.

In our process, we first shred discarded tantalum capacitors (TCs) components that can contain up to 50% tantalum by weight, then mix the shreds with carbon-rich flux materials. The microwaves rapidly heat the carbon (derived from buried polymers and adhesives), selectively triggering carbothermal reduction reactions that convert metallic compounds into sponge-like metallic alloys with high purity, particularly tantalum carbide (TaC).

This microwave-assisted process is precise, fast, and energy-efficient. In our lab tests, we have successfully recovered up to 97% pure tantalum in stable TaC form from capacitors, along with corresponding manganese products, using a three-stage controlled heating process optimized by thermodynamic modeling.

The results are promising: From just 1 ton of e-waste, this method could potentially extract around 50 pounds of critical metals, an extremely favorable yield compared to traditional methods that often recover little or none.

The significance of this innovation hasn’t gone unnoticed. We developed this technology with support from the Defense Advanced Research Projects Agency (DARPA) as part of its Recycling at the Point of Disposal (RPOD) program. While the Department of Defense’s total demand for critical materials is lower than civilian markets, their availability is of paramount importance. From radar systems and sensors to satellite electronics, modern military technology is heavily reliant on rare materials like tantalum.

Maintaining a reliable domestic supply and the ability to reclaim it from waste is a matter of national security. Disruptions from geopolitical shifts, such as reduced exports from China or political instability in Central African mines, could interrupt essential programs.

Pilot programs are now underway at West Virginia University to scale our microwave recycling method to handle larger batches, including whole smartphone boards and LED assemblies. These efforts aim to transform lab-scale success into industrial-scale impact.

Fundamentally, the widespread adoption of microwave recycling hinges on simple economics: If it becomes cheaper to extract high-value materials from used electronics than to mine them from the earth, industry will pivot. And with tantalum fetching hundreds of dollars per kilogram, profitable recycling is within reach.

Policy could accelerate adoption, too. Holding manufacturers accountable for reclaiming the materials in their devices or closing loopholes that allow e-waste to be shipped overseas for unsafe processing would help scale up recycling infrastructure. Pair that with the right technology, and the U.S. could secure a strategic reserve of rare materials while reducing environmental harm.

E-waste holds enormous potential as a form of “urban mining." In fact, end-of-life electronics may soon rival virgin mineral sources in economic viability. Today’s capacitors, circuit boards, and hard drives are tomorrow’s gold mines if we choose to see them that way.

Beyond tantalum and manganese, our microwave-assisted approach holds promise for reclaiming other elements like indium, gallium, neodymium, and silver. It's part of an emerging field of secondary mining that makes sustainability not just an environmental choice, but a strategic necessity.

That tossed-aside cellphone might hold more value than you think, not just economically, but strategically, technologically, and environmentally. With the right innovations and policy framework, microwave technology could revolutionize electronics recycling and create a cleaner, more resilient supply chain for the materials that power our modern lives.

In transforming waste into opportunity, we’re not just heating old electronics; we’re sparking a new era of sustainable manufacturing, scientific ingenuity, and resource independence.