Titanium carries with it the allure of a metal destined for greatness. It is stronger than steel but nearly half as heavy, corrosion-resistant like gold, and biocompatible enough to live inside the human body for decades. Found in abundance across the Earth's crust, in fact, it's the ninth most common element. Its ores are so inexpensive that they're used as a white pigment in toothpaste and paint. On paper, titanium should be everywhere, replacing heavier or weaker metals in everything from cars to construction. Instead, it remains a niche luxury material confined to aerospace, premium electronics, and orthopedic implants. What went wrong? Why hasn’t one of Earth’s most promising metals risen to dominate the material world alongside steel and aluminum? And given current breakthroughs, is that about to change?

Titanium was born into a world that needed speed and durability. The U.S. and Soviet militaries both raced to harness their strength-to-weight advantages in Cold War-era aircraft and submarines. Lockheed’s SR-71 Blackbird, a titanium aircraft cloaked in mystery and myth, remains one of the fastest planes ever built. But outside the rarefied worlds of military, biomedical, or high-end commercial applications, titanium has failed to become mainstream.

The reasons are not geological. With ilmenite ores containing 40–65% titanium dioxide selling for under $1 per kilogram, titanium is relatively inexpensive to extract. Theoretically, making metallic titanium from its oxide ores should require only about half the energy needed for aluminum. Yet the reality couldn’t be more different. Titanium is produced at roughly 1/5000th the volume of iron and 1/200th of aluminum. It's too expensive, too limited in supply chains, and too hard to work with.

Since the 1940s, the dominant way to produce titanium has been the Kroll process, a batch-based, complex, and touchy operation that begins by converting titanium ore into titanium tetrachloride (TiCl₄), a volatile and highly corrosive liquid. TiCl₄ is then reduced with molten magnesium in a carefully controlled environment, forming a porous titanium sponge. But this is just the beginning. That sponge must be purified under vacuum, melted into ingots, melted to remove flaws, and finally shaped into usable forms. Each step adds cost, energy, material waste, and time. The cumulative result is that titanium components, despite modest raw material costs, often exceed $25 to $50 per kilogram.

This high cost has nothing to do with a lack of raw material. Titanium ore is abundant. The issue is that each of the many stages required to reach usable metal each with its own infrastructural, chemical, and economic hurdles. The reactivity of titanium is partly to blame. Molten titanium readily absorbs oxygen, hydrogen, and nitrogen, becoming brittle and unsuitable for high-stress applications. Even solid titanium heated in air starts absorbing oxygen around 600°C, again degrading performance. This stubborn behaviour makes forming, melting, and welding titanium both difficult and wasteful. For forging operations alone, up to 50% of the material can be lost due to oxidation, a catastrophic yield loss that crushes any hope of cost efficiency.

Add to that titanium’s capacity to ruin cutting tools, require exotic protective environments, and resist forming into complex shapes, and it's no wonder titanium has barely moved down the cost curve in decades.

It’s not for lack of trying. Since Kroll, dozens of academic and industrial initiatives have attempted to disrupt titanium production, testing everything from direct oxide electrolysis to plasma reduction and alternative fuels.

The results have been sobering. None of the alternative methods, despite elegant theory and promising laboratory results, has unseated Kroll. Electrolytic approaches often hit thermodynamic traps where titanium's multiple valence states cause redox cycling, preventing metal deposition. Others, like additive manufacturing, offer some efficiency improvements but struggle with micro-porosity and cost-effectiveness at high volumes. Yet despite these roadblocks, a new wave of technologies, players, and geopolitical momentum is now stirring the titanium industry into transformation.

Developed by Dr. Zak Fang at the University of Utah and now commercialized by IperionX, HAMR tweaks the old formula in a subtle but powerful way. Instead of starting with titanium chloride, HAMR begins with titanium oxide powder and uses a hydrogen-rich environment to weaken the Ti–O bond. This allows magnesium to be a less effective reductant on its own to successfully liberate titanium with lower oxygen contamination.

The output is a brittle titanium hydride powder, ideal for shaping or sintering into final parts. After milling, the hydrogen is removed under vacuum, leaving behind a fine, pure titanium powder. This approach not only bypasses the need for TiCl₄ and many downstream processing steps but also allows recycling of high-oxygen titanium scrap (a major waste stream in the aerospace industry), giving it new life as powder suitable for additively manufactured parts. Already, IperionX is scaling HAMR at a pilot facility in Virginia, with U.S. Department of Defense backing totalling tens of millions of dollars. Initial costs for titanium powder are projected at $30/kg, dramatically below the current $200/kg cost of powders derived from atomized Kroll ingot.

Meanwhile, two very different electrolytic processes are showing potential.

The first, the FFC Cambridge process (developed in the 1990s), reduces solid titanium oxide in molten calcium chloride. It produces sponge or powder directly while sidestepping the chloride precursor entirely. UK-based Metalysis owns commercial rights and is marketing the process for high-value alloyed powders that are hard to make with Kroll.

The second, the UAT process (Universal Achemetal Titanium), takes a different tack. It reduces titanium oxycarbide anodes in molten salt electrolysis, allowing direct separation into pure metal. Crucially, UAT claims it can handle impure titanium ores like ilmenite directly, something Kroll cannot do without extensive upgrading. Both methods are being developed with funding and strategic interest from defense and industrial players in the U.S. and Europe, drawn not just by cost savings but by the promise of localized, geopolitically secure supply chains.

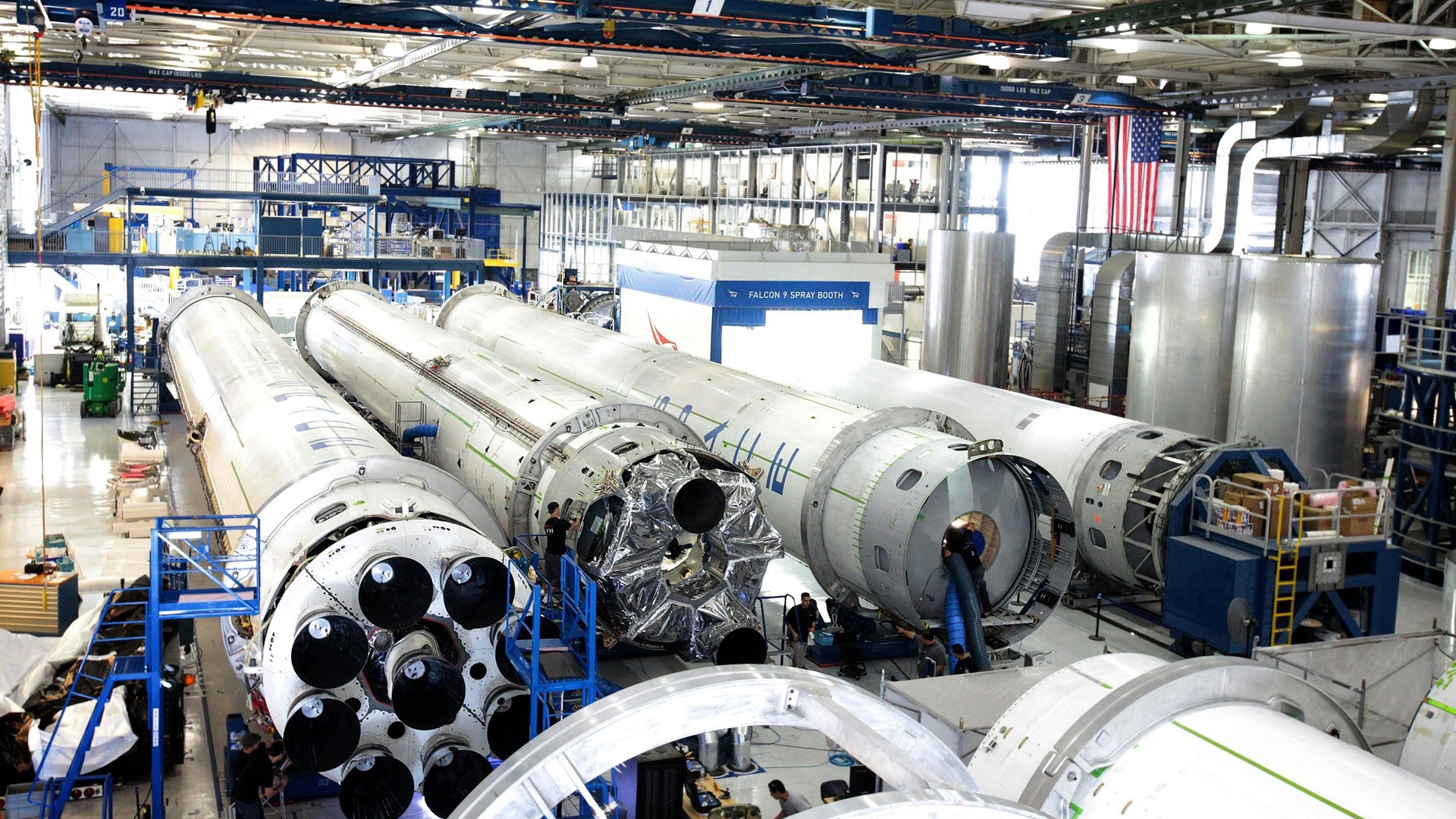

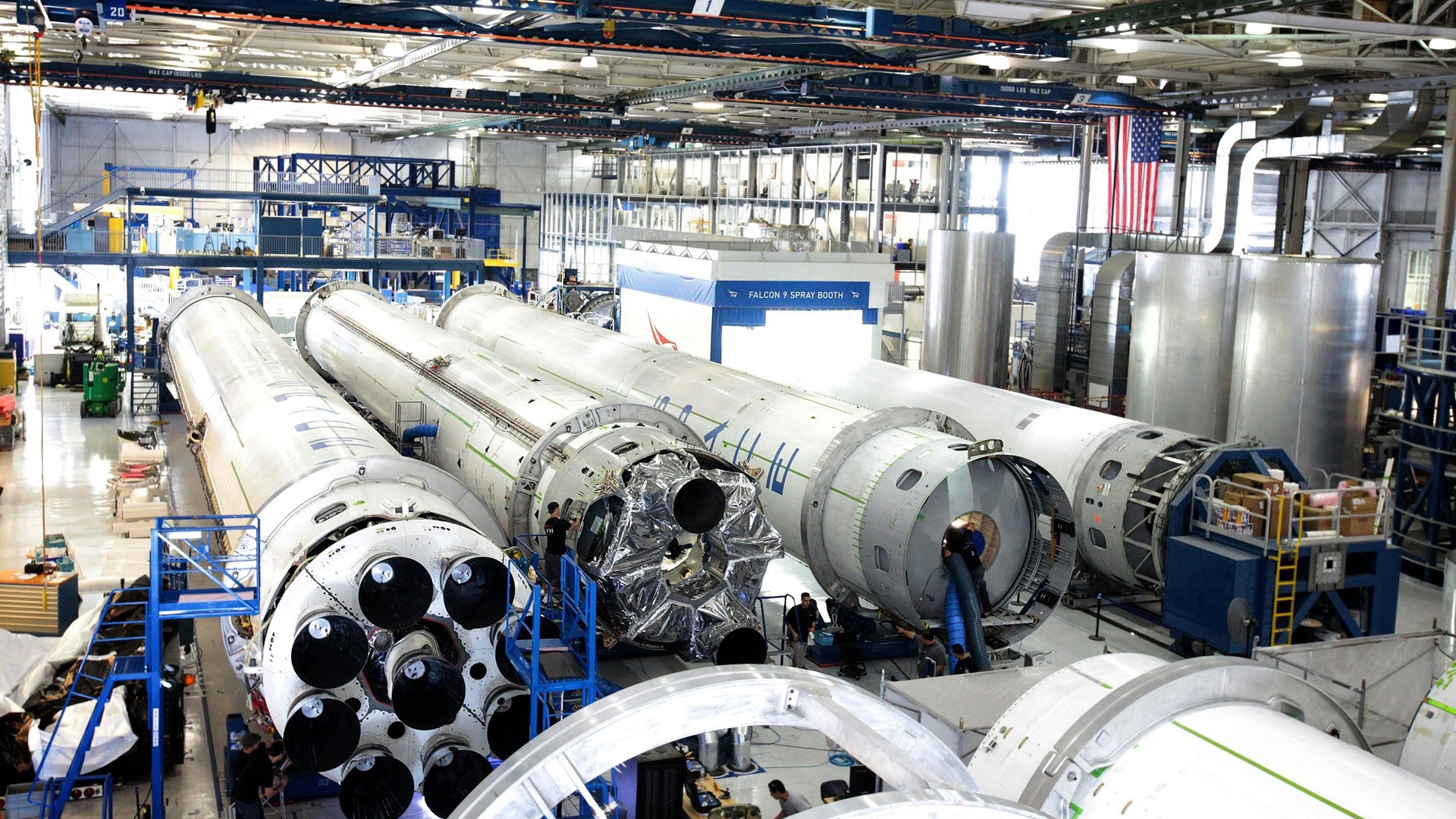

If you can make titanium more cost-effectively at the powder or wire level, the next trick is avoiding the “buy-to-fly” tragedy of subtractive manufacturing. As it stands, aerospace giants often need to purchase 20 to 40 kg of titanium ingot to machine one usable kilogram, a brutal inefficiency.

Additive manufacturing, particularly methods like Directed Energy Deposition (DED) and Laser Powder Bed Fusion (LPBF), offers game-changing potential. Norsk Titanium, for instance, has created FAA-certified components via plasma-based 3D deposition processes, halving waste compared to traditional manufacturing.

Now, with cheaper, directly produced powder from the likes of IperionX or Metalysis, there is an opportunity for synergy: high-quality titanium parts made with minimal waste, compelling cost structures, and versatile geometries that conventional machining can't replicate.

The shift toward alternative titanium production is being accelerated not purely by innovation but also by national urgency. The U.S. no longer has a domestic commercial source of titanium sponge. It relies largely on Japan, with some sourcing from China and Russia for this critical metal. This has sparked growing concerns about defense readiness and led to direct intervention from the Department of Defense and the Department of Energy.

These tailwinds, combined with the rising demand for strong, lightweight metals in aerospace, EVs, and renewable infrastructure, create the ideal environment for titanium to finally become the structural metal it always had the potential to be.

Given the abundance of titanium in Earth’s crust and the streamlining of its production chain via the likes of HAMR and UAT, researchers and industrial leaders see a path to titanium at $10–$30 per kilogram well within the ARPA-E target that would allow broad substitution for steel and aluminum in mass-market applications.

However, titanium won’t replace those metals entirely. In many applications, geometry and design trump raw material performance. Aluminum frames can outperform titanium ones simply because they can be made with larger cross-sections, thanks to lower density and ease of forming. Steel will remain dominant where cost and stiffness are critical. And composites often win where corrosion resistance and ultimate strength-to-weight matter most.

Even so, cheaper titanium throws open the doors to new possibilities. Imagine automotive engine parts designed for both strength and ultra-low mass. Medical implants are available at a fraction of today’s cost. Lightweight consumer electronics assembled from recycled titanium swarf.

What finally breaks the Titanium Paradox may not be a single breakthrough, but the convergence of many: energy abundance, supply chain policy, process innovation, and additive design. As these trends crystallize, we may be entering a decade of disruption that unlocks a future previously thought locked behind an impossibly expensive metal.